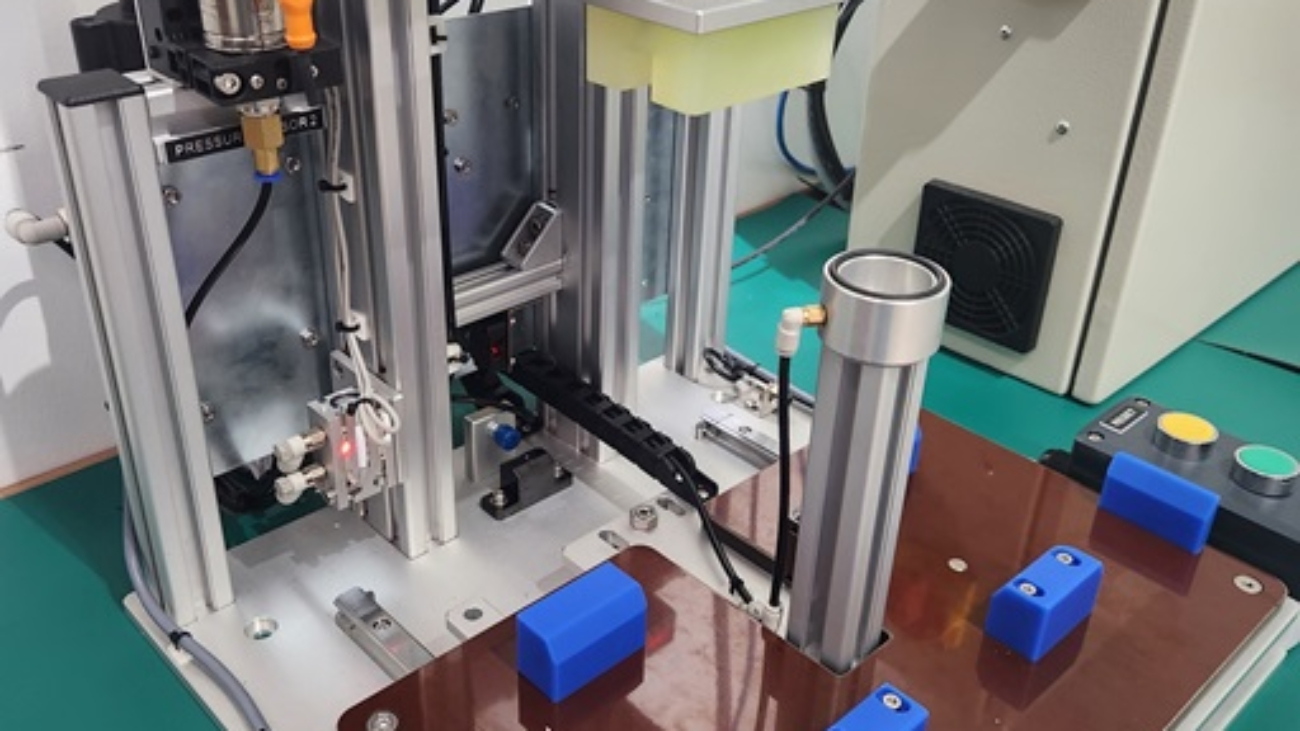

Developed exclusively for Coway’s R&D Centre, features a cutting-edge, custom-built system designed to optimize water management with precision control. This advanced system includes a CVCF power supply, which ensures reliable and efficient energy distribution, tailored specifically for the needs of the facility.

Key features of the system include:

- Flowrate Control and Monitoring: The system provides real-time monitoring and adjustment of water flow, allowing for consistent performance and operational efficiency.

- Water Pressure Control and Monitoring: Precision regulation of water pressure is maintained, ensuring optimal system operation while preventing potential issues related to pressure fluctuations.

- Stainless Steel Water-Resistant Control Panel: The control panel is built with durable, water-resistant stainless steel, offering long-term reliability and protection in demanding environments.

This project exemplifies our commitment to delivering high-quality, specialized solutions that enhance operational efficiency and reliability for leading companies like Coway.