In today’s fast-evolving industrial landscape, mobile robots have become essential tools for improving productivity, reducing labor strain, and increasing operational efficiency. Two of the most common solutions are:

Automated Guided Vehicles (AGVs)

Autonomous Mobile Robots (AMRs)

While both are designed to move materials from point A to point B, they differ significantly in technology, flexibility, and ideal use cases. Choosing the right one depends on your operational needs, environment, and long-term strategy.

PLCs in 2026: Is It Still a Thing?

In 2026, the industrial landscape continues to evolve at a breakneck pace, shaped by advances in artificial intelligence, cloud computing, robotics, and edge devices. Amid all this innovation, a question persists: Is the programmable logic controller (PLC) still relevant?

The answer is a resounding yes. PLCs haven’t been replaced; they’ve adapted and integrated into a rapidly changing automation ecosystem.

Why do PLCs still matter?

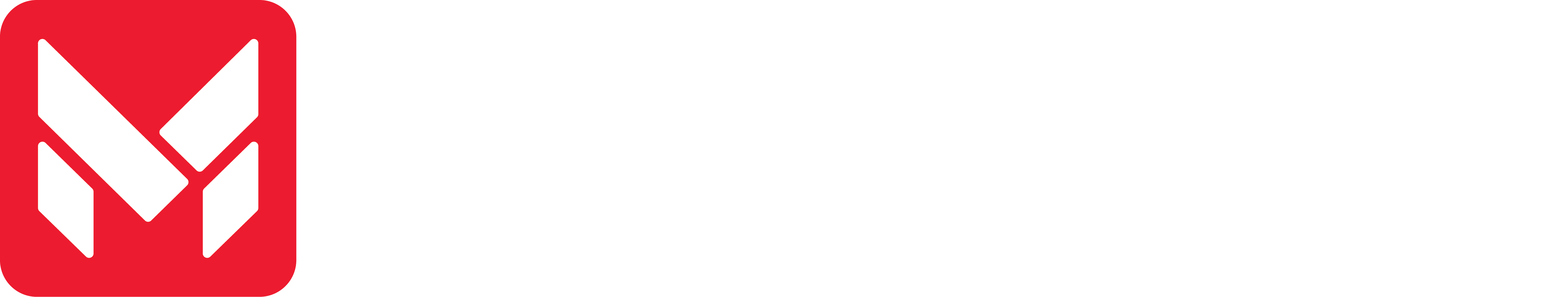

Automation in Malaysia: Momentum or Slow Burn in 2026?

Industrial automation in Malaysia remains a key focus for policy makers, manufacturers, and technology companies as the country continues its transformation toward smarter, more efficient manufacturing.

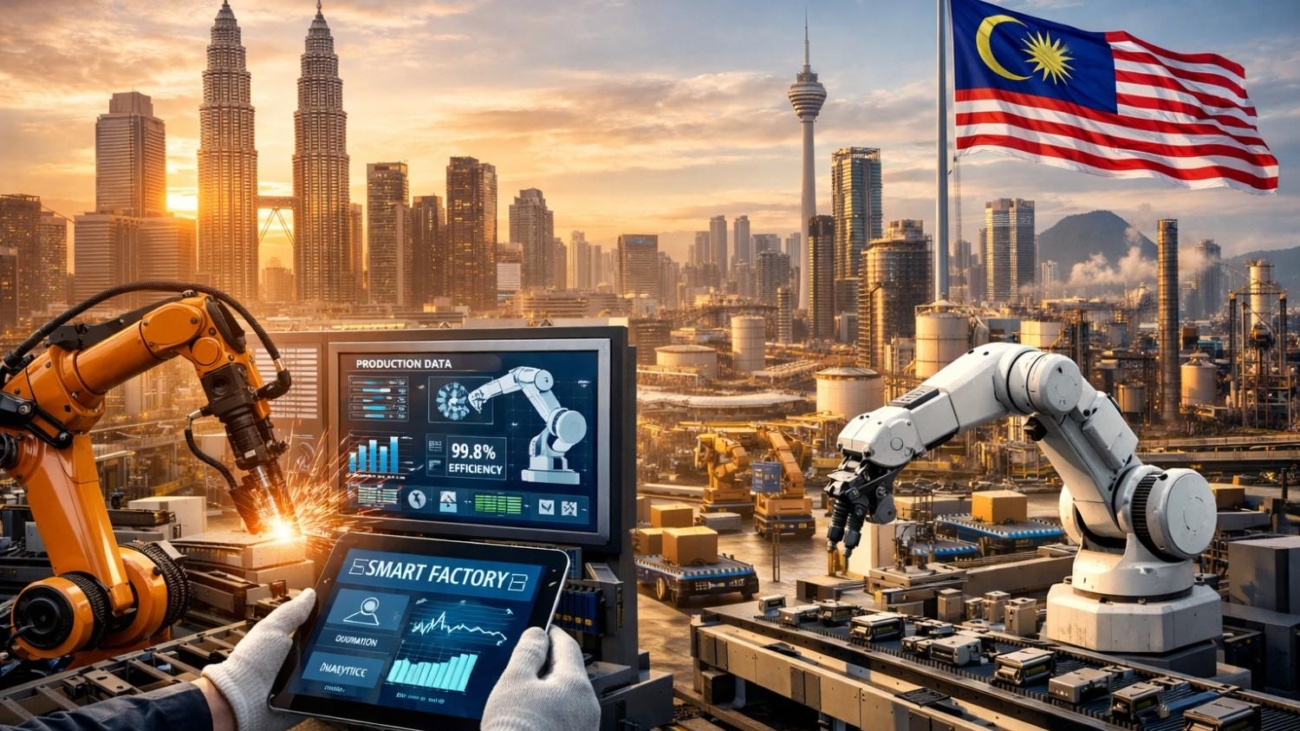

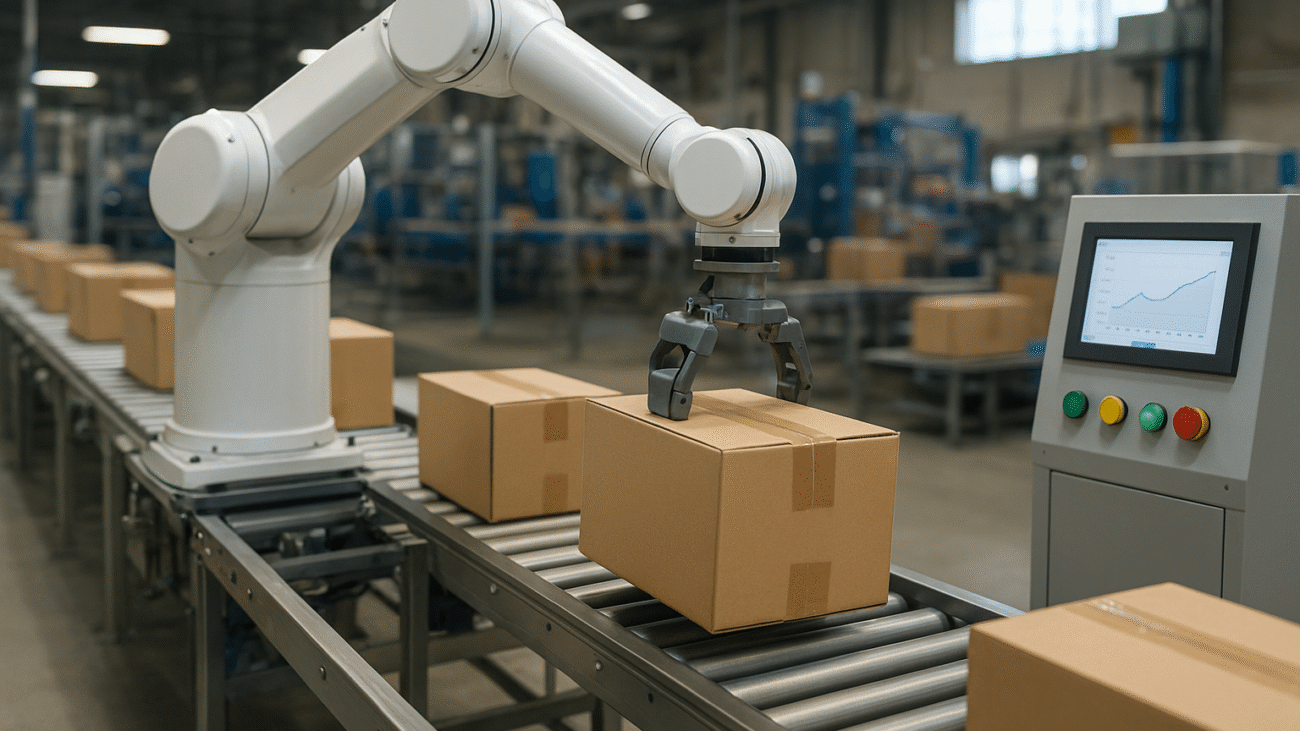

Cobot Integration to Production Lines: Key Steps and Why They Matter

A collaborative robot (cobot) is a robotic system designed to work safely alongside humans in a shared workspace. Unlike traditional industrial robots that operate inside cages, cobots are equipped with force sensors, vision systems, and safety features that allow close human interaction.

Maximise Efficiency, Minimise Taxes: Your Simple Guide to Automation Capital Allowance (ACA)

Automation Capital Allowance (ACA) is a tax incentive introduced by the Malaysian government to encourage businesses to adopt automation and modern technology in their operations. It is part of national efforts to improve productivity, efficiency, and competitiveness across the manufacturing and services sectors. Under ACA, eligible businesses can claim a 200% capital allowance on the first RM10 million of qualifying expenditure related to automation and technology investments. This allows companies to deduct more than double the actual cost from their taxable income, significantly reducing tax payable.

How Automation Works: From Data Input to Output

Every automation process starts with data input. This data can come from many sources, such as online forms, customer orders, sensors, emails, spreadsheets, or internal systems. The data provides the information needed for the automation to run. At this stage, the system may also clean, validate, or organise the data to ensure it is accurate and usable. Good-quality input data is essential, as it directly affects how well the automation performs.

Automation Is Rising in Southeast Asia, And Malaysia Is Working to Catch Up

Automation is quickly growing across Southeast Asia as companies look for faster, more efficient, and higher-quality ways to work. While progress varies across the region, Malaysia is becoming one of the most active countries pushing automation, supported by government policies and rising investment, even though it still trails global leaders.

Southeast Asia’s Journey Toward Smart Manufacturing

Southeast Asia is undergoing one of its most important industrial shifts in decades. The region, long known for cost-efficient manufacturing, is now rapidly embracing automation, AI, and connected systems to build the next generation of smart factories. And the momentum is real. Across Malaysia, Vietnam, Thailand, Indonesia, and the Philippines, companies are redesigning how they operate. What was once manual and labour-intensive is now becoming digital, data-driven, and automated.

How Motion Control Technology Is Transforming Malaysia’s Packaging Industry

Malaysia’s packaging sector is moving fast. Rising e-commerce, stricter quality standards, labour pressures, and sustainability demands are pushing manufacturers to replace legacy machines with smarter, motion-driven systems. So, what’s driving this transformation, and how is it reshaping packaging lines across Malaysia? Let’s dive in together.

Tariffs and Technology: What They Mean for Malaysia’s Automation Industry

In recent years, Malaysia’s manufacturing sector has been on a determined march toward greater automation and Industry 4.0 adoption. However, an underappreciated factor shaping this progress is trade policy, particularly tariffs, both on imports into Malaysia and on Malaysian exports.

For local manufacturers and technology adopters, understanding how these tariffs influence costs, supply chains, and investment decisions has become increasingly important. Let’s break down how tariffs are shaping Malaysia’s automation journey.