Ultra-thin stage with electric actuators placed on the single plane

- It makes the center of gravity of the entire equipment lower enough.

- Various table movements are possible by operating three actuators placed on the single plane individually.

Operating Principle

Driving the U axis moves the table in the X direction

Driving the V and W axes the same amount in the same direction moves the table in the Y direction

Driving the V and W axes the same amount in the same direction while driving the U axis moves the table diagonally

Example of rotating the table using the table center as the axis of rotation (θ axis)

Example of rotating the table using an arbitrary point as the axis of rotation (θ axis).

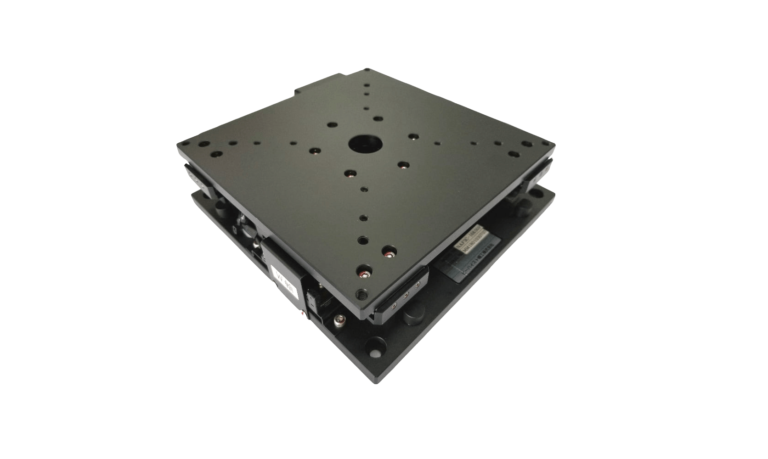

NAF3series Type-C

NAF3 Series Type-C uses “preloaded double slide structure”, which places an intermediate plate sandwiched between two upper and lower plates for 3-axis actuator (U/V/W) and slide section.

Lots of balls placed between each plate allow smooth planar rolling motion, “Preloaded double slide structure” makes stages thin, compact and highly rigid for highly accurate positioning.

NAF3series Type-D

Type-D does not use “preloaded double slide structure”, Type-D possesses unique advantages with a wide range of motion and a larger central opening.

Applications for NAF3 series

- semiconductor manufacturing equipment, testing equipment.

- Panel joining and mounting equipment(LCD, EL, touch panel, solar cell).

- Printing equipment(Chip components, PCB, FPC).

- Microscope stage and so forth.

System Configuration Drawing

Product Specifications

NAF3C-10-01P

| Properties | NAF3C-10-01P |

|---|---|

| Stroke *1 | XY±2mm・Θ±2° |

| Table size | 100mm x 100mm |

| Base size | 120mm x 120mm |

| Height | 35mm |

| Unidirectional repeatability | Within ±1μm |

| Bidirectional repeatability | Within 3μm |

| Static load capacity *2 (Distributed loading for the vertical equal position) | 200N |

| Dynamic load capacity *2 (Distributed loading for the vertical equal position) | 100N |

| Parallelism | 30μm |

| Stepping motor model | PK513PA Product of ORIENTAL MOTOR |

| Servo-motor model | – |

| Ball screw lead | 1㎜ |

| Driver model *3 | Stepping:MC-S0514-3L / Product of MICROSTEP Co. |

| Resolution (factory setting) | Stepping:0.2μm/pulse / Servo:0.1μm/pulse |

| Photomicrosensor *4 | PM-L25 / Product of Panasonic Industrial Devices SUNX |

| Stage material | Iron: Low-temperature black chrome treatment Aluminum: black anodized |

| Weight | 2.2kg |

| Lubricant | Low dusting grease |

*1 It is feasible for each axis to commence its movement simultaneously from the origin position(center of the top table), enabling a full stroke operation, if required.

*2 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*3 The driver for the stepping motor is of an open-loop configuration.

*4 There are 3 photo micro sensors on drive module on each axis.

NAF3C-16K00

| Properties | NAF3C-16K00 *1 |

|---|---|

| Stroke *2 | XY±5mm・Θ±3° |

| Table size | 160mm x 160mm |

| Base size | 170mm x 170mm |

| Height | 45mm |

| Unidirectional repeatability | Within ±0.7μm |

| Bidirectional repeatability | Within 2μm |

| Static load capacity *3 (Distributed loading for the vertical equal position) | 1000N |

| Dynamic load capacity *3 (Distributed loading for the vertical equal position) | 300N |

| Degree of parallelism | 30μm |

| Stepping motor model | TS3664N16E2 Product of TAMAGAWA SEIKI Co. |

| Servo-motor model | HG-AK0236(20W) Product of Mitsubishi Electric Corporation |

| Ball screw lead | 1㎜ |

| Driver model *4 | Stepping:MC-S0514-3L / Product of MICRO STEP Servo-amplifier :MR-J4-03A6 Product of Mitsubishi Electric Corporation |

| Resolution (factory setting) | Stepping:0.2μm/pulse / Servo:0.1μm/pulse |

| Photomicrosensor *5 | PM-L25 / Product of Panasonic Industrial Devices SUNX |

| Stage material | Iron: Low Temperature black chrome plating treatment / Aluminum: black anodizing |

| Weight | 6kg |

| Lubricant | Low dusting grease |

*1 Please choose either stepping motor (type-P) or servo motor (type-S).

*2 It is possible for each axis to be in full stroke at its starting point (at the center of the top table).

*3 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*4 The driver for the stepping motor is in open corrector specification.

*5 There are 3 photo micro sensors on drive module on each axis.

NAF3C-20K01

| Properties | NAF3C-20K01 *1 |

|---|---|

| Stroke *2 | XY±5mm・Θ±3° |

| Table size | 200mm×200mm |

| Base size | 220mm x 220mm |

| Height | 65mm |

| Unidirectional repeatability | Within ±1μm |

| Bidirectional repeatability | Within ±2μm |

| Static load capacity *3 (Distributed loading for the vertical equal position) | 2000N |

| Dynamic load capacity *3 (Distributed loading for the vertical equal position) | 600N |

| Degree of parallelism | 30μm |

| Stepping motor model | PK543NAW Product of ORIENTAL MOTOR |

| Servo-motor model | HG-KR053(50W) Product of Mitsubishi Electric Corporation |

| Ball screw lead | 1㎜ |

| Driver model *4 | Stepping:MC-S0514-3L / Product of MICRO STEP Servo-amplifier :MR-J4-10A Product of Mitsubishi Electric Corporation |

| Resolution (factory setting) | Stepping:0.2μm/pulse / Servo:0.1μm/pulse |

| Photomicrosensor *5 | PM-L25 / Product of Panasonic Industrial Devices SUNX |

| Stage material | Iron: Low Temperature black chrome plating treatment / Aluminum: black anodizing |

| Weight | 14kg |

| Lubricant | Low dusting grease |

*1 Please choose either stepping motor (type-P) or servo motor (type-S).

*2 It is possible for each axis to be in full stroke at its starting point (at the center of the top table).

*3 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*4 The driver for the stepping motor is in open corrector specification.

*5 There are 3 photo micro sensors on drive module on each axis.

NAF3C-30K00

| Properties | NAF3C-30K00 *1 |

|---|---|

| Stroke *2 | XY±5mm・Θ±3° |

| Table size | 300mm x 300mm |

| Base size | 320mm x 320mm |

| Height | 70mm |

| Unidirectional repeatability | Within ±1μm |

| Bidirectional repeatability | Within ±2μm |

| Static load capacity *3 (Distributed loading for the vertical equal position) | 4000N |

| Dynamic load capacity *3 (Distributed loading for the vertical equal position) | 1000N |

| Degree of parallelism | 30μm |

| Stepping motor model | PK546PA / Product of ORIENTAL MOTOR |

| Servo-motor model | HG-KR053(50W) Product of Mitsubishi Electric Corporation |

| Ball screw lead | 2mm |

| Driver model *4 | Stepping:MC-S0514-3L / Product of MICRO STEP Servo-amplifier:MR-J4-10A / Product of Mitsubishi Electric Corporation |

| Resolution (factory setting) | Stepping:0.2μm/pulse / Servo:0.1μm/pulse |

| Photomicrosensor *5 | PM-L25 / Product of Panasonic Industrial Devices SUNX |

| Stage material | Iron: Low Temperature black chrome plating treatment / Aluminum: black anodizing |

| Weight | 44kg |

| Lubricant | Low dusting grease |

*1 Please choose either stepping motor (type-P) or servo motor (type-S).

*2 It is possible for each axis to be in full stroke at its starting point (at the center of the top table).

*3 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*4 The driver for the stepping motor is in open corrector specification.

*5 There are 3 photo micro sensors on drive module on each axis.

NAF3C-40K00

| Properties | NAF3C-40K00 *1 |

|---|---|

| Stroke *2 | XY±5mm・Θ±3° |

| Table size | 400mm x 400mm |

| Base size | 400mm x 400mm |

| Height | 80mm |

| Unidirectional repeatability | Within ±1μm |

| Bidirectional repeatability | Within ±2μm |

| Static load capacity *3 (Distributed loading for the vertical equal position) | 6000N |

| Dynamic load capacity *3 (Distributed loading for the vertical equal position) | 1000N |

| Degree of parallelism | 30μm |

| Stepping motor model | PK546PA / Product of ORIENTAL MOTOR |

| Servo-motor model | HG-KR053(50W) Product of Mitsubishi Electric Corporation |

| Ball screw lead | 2mm |

| Driver model *4 | Stepping:MC-S0514-NF-3L / Product of MICRO STEP Servo-amplifier:MR-J4-10A / Product of Mitsubishi Electric Corporation |

| Resolution (factory setting) | Stepping:0.2μm/pulse / Servo:0.1μm/pulse |

| Photomicrosensor *5 | PM-L25 / Product of Panasonic Industrial Devices SUNX |

| Stage material | Iron: Low Temperature black chrome plating treatment / Aluminum: black anodizing |

| Weight | 60kg |

| Lubricant | Low dusting grease |

*1 Please choose either stepping motor (type-P) or servo motor (type-S).

*2 It is possible for each axis to be in full stroke at its starting point (at the center of the top table).

*3 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*4 The driver for the stepping motor is in open corrector specification.

*5 There are 3 photo micro sensors on drive module on each axis.

NAF3D-40K02

| Properties | NAF3D-40K02 *1 | ||

|---|---|---|---|

| Stroke *2 | XY±5mm・Θ±3° | ||

| Table size | 400×400mm (Center hole:□125) | ||

| Base size | 400×400mm (Center hole:□125) | ||

| Height | 85.4mm | ||

| Unidirectional repeatability | Within ±1μm | ||

| Bidirectional repeatability | - | ||

| Static load capacity *3 (Distributed loading for the vertical equal position) | 6000N | ||

| Dynamic load capacity *3 (Distributed loading for the vertical equal position) | 1000N | ||

| Degree of parallelism | 50μm (measured on each axis) | ||

| Stage material | Iron:Low Temperature black chrome plating treatment / Aluminium:black anodizing | ||

| Ball screw lead | 1mm | ||

| Stepping motor model | Motor model | PKP546N18A / Product of ORIENTAL MOTOR | |

| Driver model *4 | MC-S0514-3L / Product of MICRO STEP | ||

| Resolution (factory setting) | 0.2μm/pulse | ||

| Servo-motor model | Motor model | HG-KR053 / Product of Mitsubishi Electric Corporation | |

| Driver model | MR-J4-10A / Product of Mitsubishi Electric Corporation | ||

| Resolution (factory setting) | 0.1μm/pulse | ||

| Photomicrosensor *5 | PM-L25 / Product of Panasonic Industrial Devices SUNX | ||

| Weight | 45kg | ||

| Lubricant | Low dusting grease | ||

*1 Please choose either stepping motor (type-P) or servo motor (type-S).

*2 It is possible for each axis to be in full stroke at its starting point (at the center of the top table).

*3 This is the capacity for a vertically evenly distributed load. To be loaded on to conveyance stage or other cases, the number above will not apply.

*4 The driver for the stepping motor is in open corrector specification.

*5 There are 3 photo micro sensors on drive module on each axis.

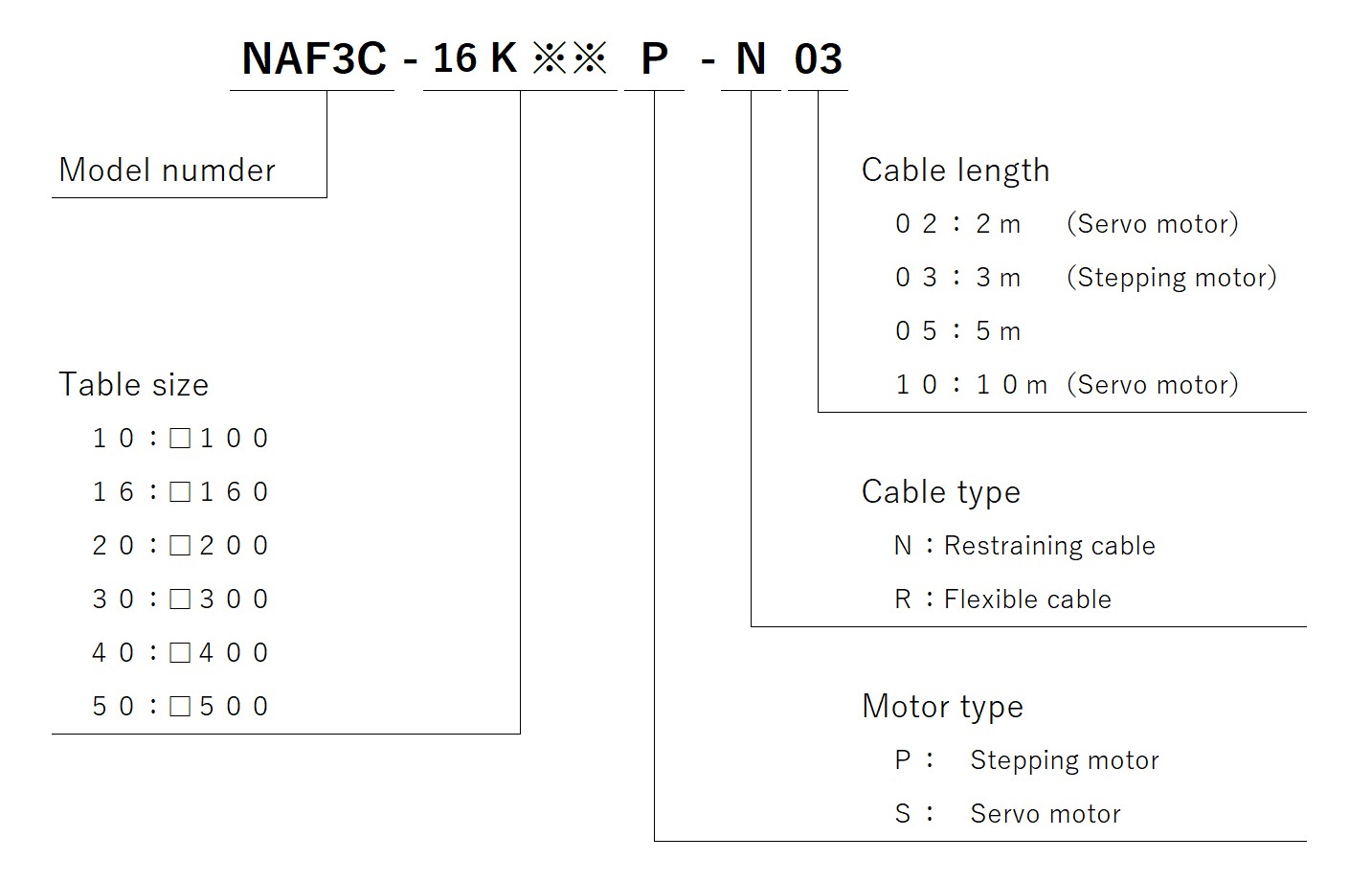

Model number notation