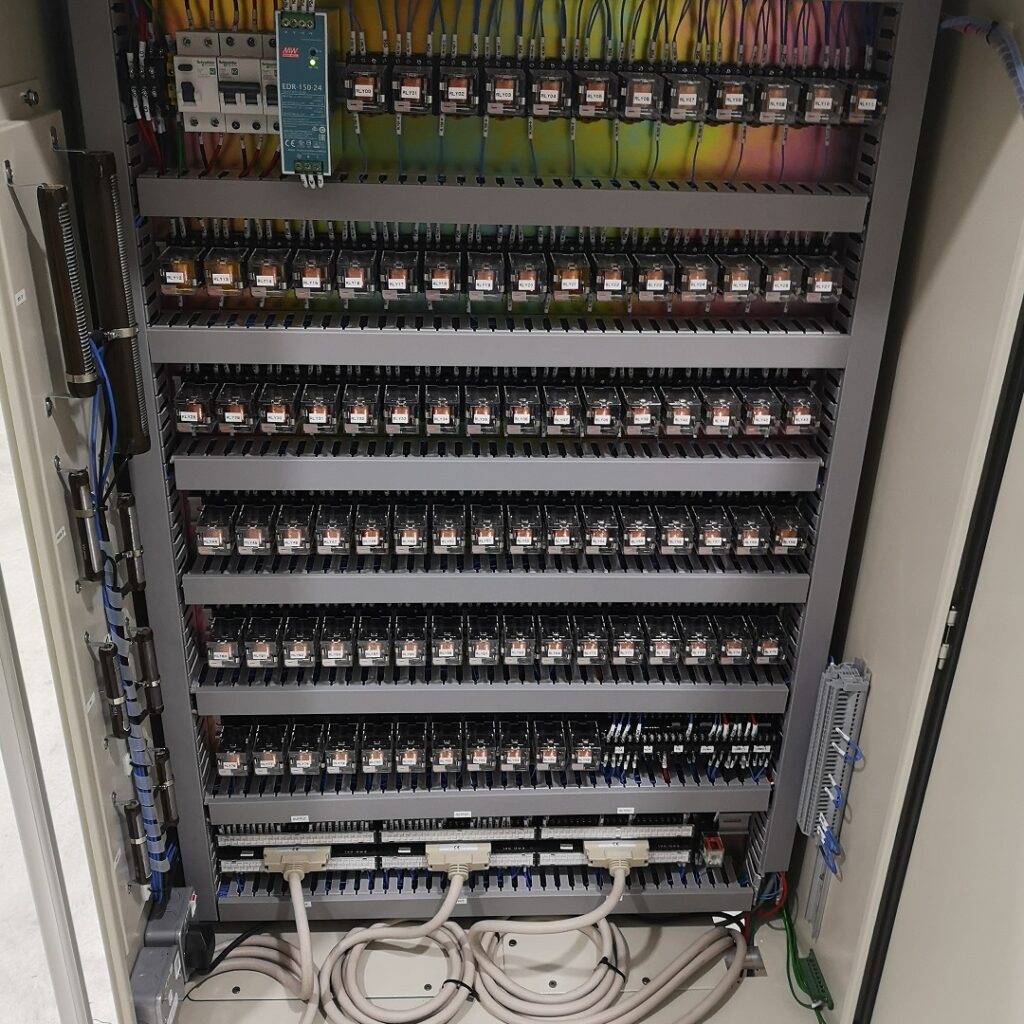

In response to our customer’s requirements, we have developed a custom I/O module tester machine designed to comprehensively assess all necessary specifications for the I/O modules. For input modules, the testing criteria include verifying the ON/OFF state voltage, minimum and maximum ON state current, and OFF state current. For output modules, we evaluate load operation, saturation voltage, and OFF state current leakage. Additionally, both input and output modules undergo testing for their Fore Ground (FG) connections to ensure all FG connections are properly linked. The machine is capable of testing both AC and DC currents and voltages, with a current measurement range from 1,000 µA to 3A and a voltage measurement range from 100mV to 700V. Its design allows for the testing of up to 20 different I/O modules, thanks to its interchangeable jigs.

The machine’s primary controller utilizes a PC equipped with custom software to monitor all necessary I/O modules. Although the machine employs a PLC, its primary role is to verify that each I/O module is properly connected and can communicate with the PLC CPU before testing begins. The PLC communicates with the PC through RSLinx software using DDELink communication, confirming that there are no faults in the I/O modules, allowing the machine to proceed with testing. Each I/O module is tested individually to ensure that it meets all required specifications and functions correctly.

- PC Tester System

- Current Tester

- Voltage Tester

- Full Load Tester

- Advantech Industrial PC

- Allen Bradley PLC