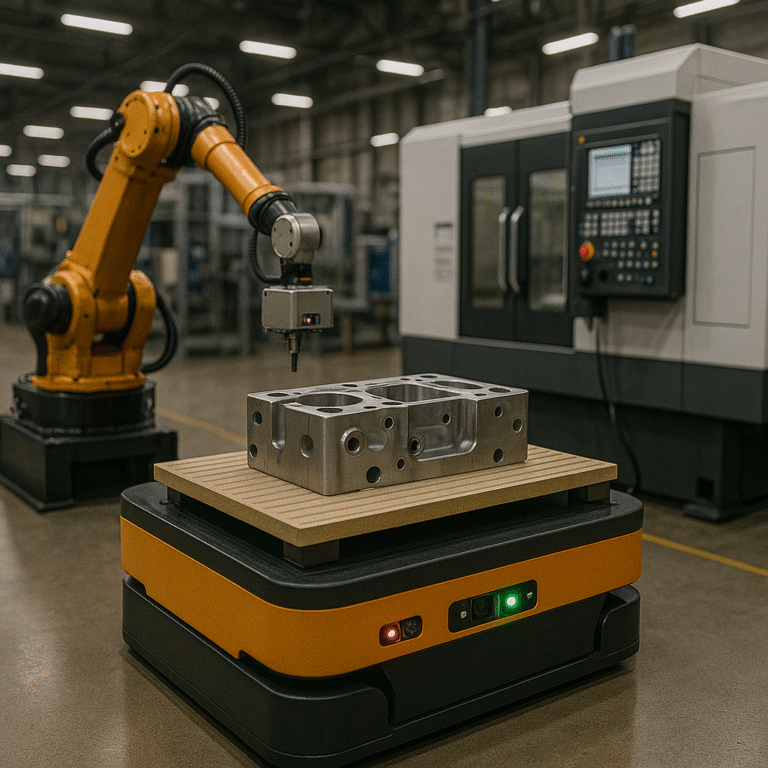

We live in a world where machines build our cars, pack our groceries, and sort our packages at lightning speed. Automation is no longer the future—it’s the present. But there’s one critical piece that often gets overlooked: maintenance.

Machine maintenance is not just fixing things when they break. It’s about preventing failure before it happens. It’s about protecting the massive investments we’ve made in automation and ensuring the precision and performance we count on every day.

Because when a single machine goes down, it doesn’t just stop production—it can stop progress.

Every minute a machine is offline, we lose more than production.

We lose momentum.

We lose trust.

We lose our competitive edge.

A single machine breakdown can ripple through a supply chain, delay shipments, disappoint customers, and erode brand reputation. But here’s the good news: most of that downtime is preventable, with the help of maintenance!

With the help of scheduled maintenance, predictive diagnostics, and real-time monitoring, these allow us to stay ahead of the curve. They empower us to plan instead of react.

Therefore, routine maintenance keeps quality high, downtime low, and workers safe.

The future is predictive—and it starts now.

We’re entering a world where machines tell us when they need help. Remember this – Automation makes us faster, but maintenance keeps us going.

So let’s stop treating machine maintenance as the backstage crew and start giving it the spotlight it deserves. Because when we do, we unlock not just the potential of our machines—but the full power of human ingenuity.