High Rigidity and High Precision with Zero Clearance Rolling Guideways

The essential multi-degree-of-freedom joints for parallel mechanisms have conventionally been obtained 2 to 3 degrees of freedom with combinations of spherical joints. However, such spherical joints combinations often lead to structural complexity and bulkiness. There are multi-degree-of-freedom sliding spherical ball bearings available, but they come with large frictional resistance and internal clearance issues. Hephaist has developed SRJ – Spherical Rolling Joints as the solutions to all these issues.

Features

- High precision

The moving parts of SRJ are preloaded rolling bearing structure, and it makes SRJ achieved high accuracy with low frictional resistance and zero clearance.

Highly Suited for Parallel Mechanisms

Optimal for parallel mechanisms requiring high precision, high rigidity, and compactness.

- Downsizing

SRJ achieving higher rigidity and downsizing compared to a combination of rolling bearings with 3 degrees of freedom.

- Super-Precise Spherical Surface Processing

Unique Hephaist processing technology provides super-precise spherical surfaces.

Dimension Chart

| Model number | ΦA | ΦB | C | D | E | F | G | ΦH (spigot joint) | ΦI | J | K (Thread runout section) | ΦL Drill, U counterbore, Depth | M (Width across flats) | ΦN | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SRJ004C | 19, 0-0.008 | 15 | 3.8 | 2.5 | 10 | 6 | M3 | 3.6, -0.004 -0.012 | 4.5 | 2 | 1 | 4-2, φ3.5, 1.5 | 4 | 6 | 1.5 |

| SRJ006C | 25, 0 -0.013 | 20 | 5.5 | 3.8 | 11.5 | 8 | M4x0.5 | 4.5, -0.004 -0.012 | 6 | 2 | 1 | 4-3, φ5, 2.3 | 5 | 10 | 2 |

| SRJ008C | 30, 0 -0.021 | 24 | 7 | 4 | 16 | 12 | M5×0.5 | 5.5, -0.004 -0.012 | 8 | 4 | - | 4-3.4, φ6, 2 | 7 | 11 | 2 |

| SRJ012C | 42, 0 -0.02 | 34 | 11 | 6 | 20 | 15 | M10 | 11, -0.006 -0.017 | 16 | 2 | 2 | 4-4.3, φ8, 3.6 | 14 | 14 | 2 |

| SRJ016C | 56, 0 -0.03 | 45 | 12 | 7 | 32 | 18 | M12 | 12.6, -0.006 -0.017 | 16 | 3 | - | 4-5.5, φ9.5, 4.6 | 14 | 25 | 5 |

| SRJ024C | 74, 0 -0.03 | 62 | 17 | 11 | 42 | 23 | M14 | 15, -0.006 -0.017 | 19 | 5 | - | 4-6.6, φ11, 5.5 | 17 | 35 | 7 |

| SRJ032C | 100, 0 -0.035 | 84 | 22 | 16 | 60 | 30 | M16 | 6.6, 0 -0.011 | 25 | 6 | - | 4-9, φ14, 8.6 | 22 | 48 | 10 |

| SRJ048C | 136, 0 -0.04 | 114 | 38 | 22 | 78 | 38 | M28×2 | 30, 0 -0.013 | 36 | 6 | - | 6-11, φ17.5, 10.8 | 30 | 60 | 10 |

- Delivered with rust-preventive oil as standard. If the customer specifies a grease, it will be applied.

- When the axis is turned, the retainer projects beyond the bottom of the housing, so the mounting face on the other side has to be machined to create a recess.

Material :- Housing:SUJ2/ROD:SUJ2・S45C/Retainer:C3604A-LCd

Product Specifications

| Model Number | Basic Load Rating C(N) | Basic Static Load | Permissible Load | Weight(kg) | Permissible angle of swing(°) | ||||

| C(N) | Co(N) | Axial pushing(N) | Axial pulling(N) | Radial(N) | |||||

| SRJ004C | 128 | 100 | 102 | 38 | 64 | 0.015 | ±15 | ||

| SRJ006C | 320 | 280 | 256 | 96 | 160 | 0.036 | ±30 | ||

| SRJ008C | 490 | 540 | 392 | 147 | 245 | 0.06 | ±30 | ||

| SRJ012C | 720 | 770 | 576 | 216 | 360 | 0.18 | ±30 | ||

| SRJ016C | 1170 | 1300 | 936 | 351 | 585 | 0.37 | ±30 | ||

| SRJ024C | 2840 | 3920 | 2272 | 852 | 1420 | 0.93 | ±30 | ||

| SRJ032C | 5800 | 8820 | 4640 | 1740 | 2900 | 2.3 | ±30 | ||

| SRJ048C | 10600 | 16000 | 8480 | 3180 | 5300 | 6.73 | ±30 | ||

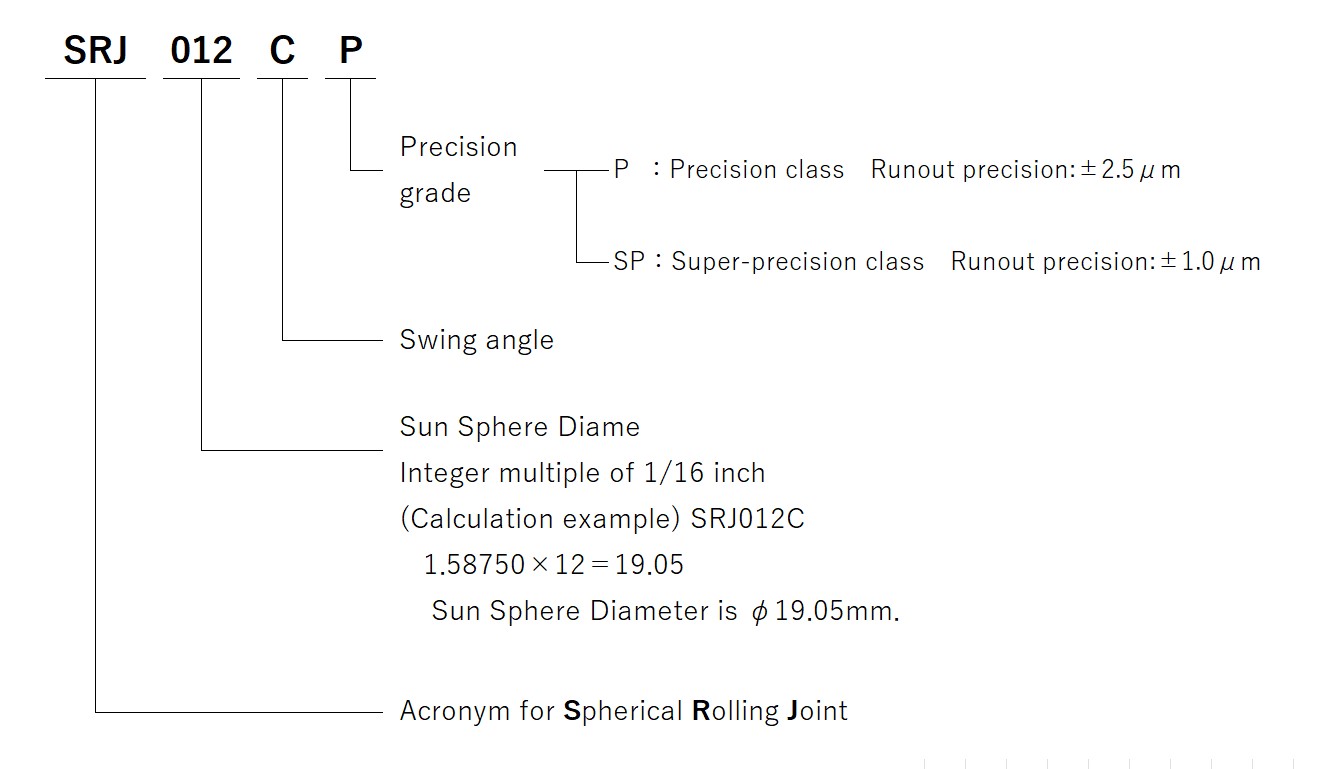

Model Configuration

The standard product material is SUJ2 (high carbon, high chromium bearing steel).

Stainless steel is also used upon request.

Surface treatment (low-temperature black chromium treatment) can also be arranged.

Precision class SP is available for items SRJ008 to SRJ032.

Technical Information

View 2D and 3D CAD data for this product.